Aero engine is a high-tech product with high comprehensive technical difficulty, only a few countries in the world can independently develop, aero engine is linked to aerodynamic performance, combustion heat transfer, strength vibration, material technology, assembly and maintenance and other advanced technology bridge and link.Under this background, blade repair technology is particularly important. By using advanced superalloy materials such as single crystal nickel-based superalloys and ceramic matrix composites (CMCs), combined with new coating technologies and sophisticated repair processes, we are able to significantly improve the heat and corrosion resistance of high-pressure turbine blades and extend their service life.

Turbine blades are important components that convert part of the energy of high temperature and high pressure gas into mechanical energy and output it by shaft power. Working in the harsh environment of high temperature and high speed, turbine blades not only have to withstand the centrifugal load, aerodynamic load, thermal load and vibration load generated by high-speed rotation, but also suffer from oxidation and vulcanization corrosion of gas. When engine working conditions are constantly changing, the interaction of various loads and damage makes turbine blades one of the components with the most structural damage failures during engine development and use. In particular, the strength of high-pressure turbine rotor blades plays a decisive role in the selection of engine thermal parameters (gas temperature in front of the turbine). It directly affects the performance and reliability of the engine. Therefore, at present, on the one hand, new superalloy materials are constantly developed to improve high temperature resistance and strength performance, and on the other hand, cooling technology is constantly developed to reduce the temperature of the rotor blade and improve the life and reliability of the blade.

The power emitted by the turbine is directly proportional to the gas temperature at the turbine inlet and the ratio of pressure before and after the turbine (drop pressure ratio). The greater the gas temperature and drop pressure ratio, the greater the power emitted by the turbine, and the better the overall engine performance. However, the ultimate pursuit of gas temperature brings the requirements for turbine blades (including guide blades and working blades) to be in a high temperature and high pressure working environment for a long time. Since then, two main measures have been derived: 1) to improve the temperature resistance of high-pressure turbine blade materials; 2) Strengthen cooling. In terms of materials, in addition to improving the composition of superalloy, it can also be achieved by improving the manufacturing process; In terms of casting process, the development from equiaxed crystal and oriented crystal to single crystal blade not only improves the high temperature resistance of the blade, but also extends the working life of the blade in a high temperature environment.

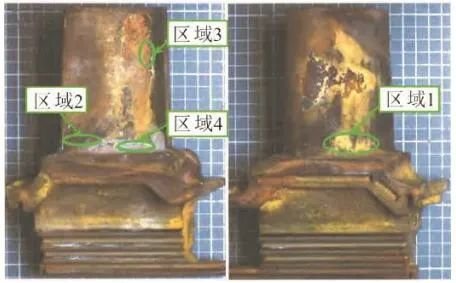

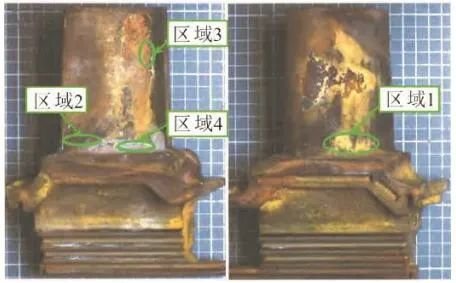

The common faults of turbine blades include cracks, grain boundary display, cracking, crystal shedding, hairlines, gas corrosion and surface damage. The surface defects of the blade body and mortise are relatively common, and about 60% of the blades with a life of more than 200h have such faults to varying degrees.

The production cost of aero engine blade is not only expensive, but also the production cycle is long, and direct replacement will cause high economic losses, and most of the damage on the blade surface can be reused through repair. Therefore, it is very meaningful to carry out research on the repair process of high-temperature alloy blade and high-pressure turbine blade, extend the life and utilization rate of parts, and reduce the demand for new parts. It must be repaired every 3-5 years, and a blade must be repaired 2-3 times in its life cycle.

Repair process flow

High-pressure turbine blade repair in international benchmark enterprises usually has a 40-step process, and the mass production quality of maintenance is guaranteed through standardized process flow. Due to the lack of standardized process experience and system, domestic maintenance often only carries out necessary process maintenance, and does not pay attention to the details and detection content of the process. The main processes are as follows:

1. Clean carbon deposits

It is mainly aimed at the deposits on the blade surface after fuel combustion and the thermal corrosion layer produced by the coating and substrate after high temperature oxidation corrosion.

2. Peel off the coating

Using a bath containing a higher concentration of pitting reagents can quickly dissolve and uniformly remove the coating.

3. Non-destructive testing

The blade profile integrity and internal structure of the blade are tested with advanced testing instruments to assess the damage and defect conditions such as wear, melting, corrosion, falling, cracking, carbon accumulation and heat dissipation hole blockage, so as to guide the detailed repair process of the blade. Including CT rays, coordinate measuring machine (CMM) accurate detection, ultrasonic detection (reflected wave signal), acoustic emission detection, infrared detection, etc., can detect whether there are cracks, peeling, sandwich and other defects in the blade.

4. Welding repair

Argon arc welding is a kind of gas shielded arc welding, and the main difference between it and the general manual arc welding is that the arc, the molten pool and the air are separated by the protective gas (argon) to eliminate the harmful effect of air, so as to obtain a good performance weld.

Laser repair is mainly based on the 3D model data of the parts to be repaired, the material is stacked point by point, line by line and layer by layer, and the matrix and powder are irradiated by high energy laser beam to form a molten pool, in which the alloy powder and the matrix achieve a good metallurgical combination. High energy laser heating is a fast melting and cooling process, small heat input to the matrix, low dilution rate, the repaired tissue has the characteristics of uniform fine, no macro segregation, and the operation is flexible and high degree of automation, in the repair parts mechanical properties and formability also has a unique advantage, make a variety of materials composite, adapt to the mechanical properties of different parts, Repair the damaged parts in different shapes and positions.

5. Fluorescence detection

Using capillary action, the permeating fluid with fluorescent material or colorant is applied to the surface of the blade. The permeating fluid penetrates into the surface defects of the turbine blade due to capillary action. After drying, the developer is applied to magnify the shape and distribution of the blade defects. This method can detect multiple blades simultaneously.

6. Recoat

Each turbine engine produced by RR, GE, PW has more than 30 kinds of surface engineering modified coatings, which will be fully reapplied during each overhaul of the engine to ensure the performance and safety of the aircraft engine, classified by function: Thermal barrier coating, high temperature oxidation corrosion resistance coating, high and low temperature wear-resistant coating, anti-seismic wear coating, fire protection coating, lubrication coating, high and low temperature sealing coating, dimensional repair coating, etc.

At present, the commonly used spraying methods in the world are plasma spraying (ceramic surface layer + metal transition layer), supersonic flame spraying (metal transition layer), explosive spraying (metal transition layer), electron beam physical vapor deposition (EB-PVD) (ceramic surface layer + metal transition layer).

In the maintenance process of aero-engine high-pressure turbine blades, the application of new materials has significantly improved the maintenance efficiency and blade performance. Through the use of advanced superalloy materials such as single crystal nickel-based superalloys, ceramic matrix composites (CMCs) and new coating technologies, we are able to effectively extend the service life of the blades and improve their reliability in extremely high temperatures and high stress environments. These new materials not only offer excellent heat and corrosion resistance, but also significantly reduce blade weight, thereby improving overall engine performance and fuel efficiency. In addition, combined with precision repair technology and strict inspection process, we ensure that every blade after repair can meet or even exceed the original design standards, providing customers with safe and reliable service. Through the continuous exploration and application of new materials, we are committed to providing the aviation industry with more efficient and durable solutions to meet the growing demand for high performance.

Thank you for your interest in our company! As a professional gas turbine parts manufacturing company, we will continue to be committed to technological innovation and service improvement, to provide more high-quality solutions for customers around the world.If you have any questions, suggestions or cooperation intentions, we are more than happy to help you. Please contact us in the following ways:

- WhatsAPP:+86 135 4409 5201

- E-mail:peter@turbineblade.net